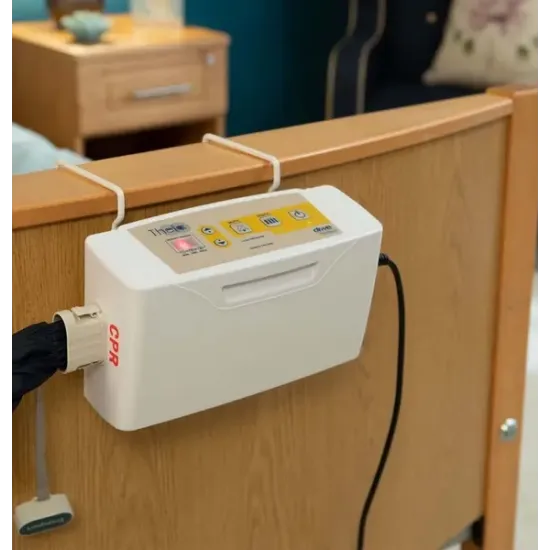

The Drive DeVilbiss Theia Digital Pump is a high-performance pressure area care solution designed to deliver versatile and reliable alternating therapy for patients at high risk of developing pressure ulcers. Engineered with a focus on clinical flexibility and ease of use, this lightweight digital pump features a 2:1 alternating cycle that provides optimal pressure redistribution. One of its standout advantages is its interchangeability; the Theia pump is compatible with various mattress systems, including foam-on-air and full-cell replacements, which significantly reduces the need for extensive staff training and lowers equipment management costs across healthcare facilities.

The pump operates with a standard 10-minute cycle time and includes a static mode for clinical procedures or patient transfers. Safety is prioritized through integrated audible and visual alarms that alert caregivers to low pressure or power failures. The intuitive digital interface also allows for precise comfort adjustments based on the patient's weight. To prevent accidental setting changes, the unit includes an automatic lock-out feature. With its compact 1.6kg design and robust hanging brackets, the Theia Digital Pump is an ideal choice for both professional clinical environments and long-term home care settings where effective, quiet, and user-friendly pressure management is essential.

Compatible with the Hybrid-Power Mattress (MAT/HYB/POWER/2), Air on Air Mattress (AIR/MAT), Air On Foam Mattress (FULL/MAT), Mattress Overlay (OVERLAY/MAT), Hybrid-Power Cushion (CUSH/HYB/POWER/2) and Air On Foam 18" Cushion (DYN/CUSH/18)

Fully EN60601-1, EN60601-1-2 and EN60601-1-11 compliant; meeting the requirements for medical electrical equipment and medical electrical systems used in the home healthcare environment

This interchangeable system reduces clinical training on multiple dedicated pumps and dynamic systems, whilst also reducing risks associated with medical devices in use due to standardised training and competency programs.

The pumps and surfaces all share several common components and spare parts, delivering cost savings whilst reducing the number of critical spare part stockholdings. This significantly reduces the cost of ownership while simplifying field service through reduced product downtime. Service support staff only have to carry minimal spare parts or one type of replacement pump to solve problems in the field; this greatly improves customer service, minimises client inconvenience and reduces downtime of critical pressure support equipment.